Electric Overhead Traveling (EOT) cranes are widely used in industries ranging from manufacturing and steel plants to warehouses and shipyards. These cranes are designed primarily for lifting, moving, and positioning heavy loads along a predetermined path. While standard EOT cranes provide robust lifting capabilities, the functionality, safety, and efficiency of these cranes can be significantly enhanced through optional attachments and accessories. These add-ons are designed to tailor the crane to specific operational needs, improve handling efficiency, increase safety, and prolong equipment lifespan.

In this article, we will explore the variety of electric overhead travelling crane attachments and accessories, their benefits, and how they can transform a standard crane into a versatile and highly efficient lifting solution.

1. Radio Remote Control Systems

One of the most impactful accessories for EOT cranes is a radio remote control system. Traditional crane operation typically involves a driver in a cabin or ground-level pendant control. However, radio remote control overhead cranes allow operators to control the crane from a safe distance, offering greater flexibility and safety.

Benefits:

-

Enhances operator visibility by allowing positioning at optimal vantage points.

-

Reduces operator fatigue by eliminating the need to remain in the cabin for long periods.

-

Increases operational safety, particularly in hazardous environments.

Radio remote systems can also integrate with limit switches and overload protection systems, providing a smart control environment that minimizes the risk of accidents.

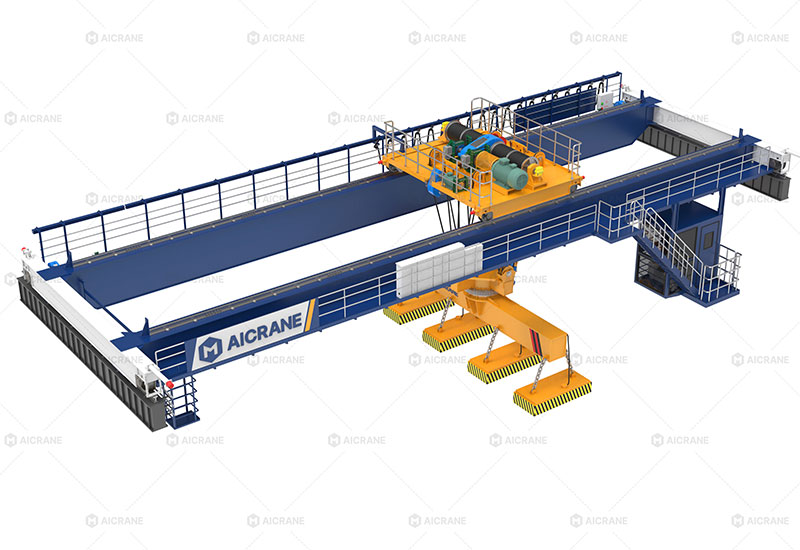

2. Magnet Attachments

For industries such as steel manufacturing, electromagnetic lifting attachments are essential. These devices use magnetic fields to lift ferrous materials such as steel plates, billets, and scrap metal efficiently.

Benefits:

-

Speeds up the handling of steel products, reducing cycle time.

-

Minimizes manual labor, enhancing worker safety.

-

Can be integrated with automatic controls for precise handling.

Permanent or electromagnets can be customized for different lifting capacities and sizes, making them versatile for various applications.

3. Grab Buckets and Clamps

Mechanical grabs and clamps are indispensable in industries where bulk materials or irregularly shaped loads are handled. The grab cranes can be hydraulic or mechanical and are designed to handle materials like coal, sand, cement, or steel rods.

Benefits:

-

Allows for the handling of bulk or irregular loads that cannot be lifted with a standard hook.

-

Improves loading and unloading efficiency.

-

Reduces risk of material spillage and damage.

Grab attachments are often combined with automation features for precise handling in high-volume operations.

4. Vacuum Lifting Systems

Vacuum lifting systems are another advanced attachment that allows EOT cranes to handle non-ferrous and delicate materials, including glass panels, aluminum sheets, and plastic components. These systems create a suction force using vacuum pads to lift the load safely.

Benefits:

-

Enables lifting of delicate materials without causing damage.

-

Reduces manual labor and risk of accidents.

-

Can be adapted for different load sizes and shapes.

Vacuum lifters can be integrated with adjustable pads, ensuring the load is lifted evenly and securely.

5. Weighing Systems

For operations where load monitoring is critical, on-crane weighing systems are invaluable. These systems measure the weight of the lifted material in real time and provide accurate data to operators.

Benefits:

-

Prevents overloading, ensuring compliance with crane load limits.

-

Helps maintain safety and operational efficiency.

-

Provides data for inventory management and process optimization.

Modern digital weighing systems can be connected to control panels and software for automated data logging and reporting.

6. Anti-Sway and Load Stabilization Devices

Load sway is a common challenge when lifting heavy loads, particularly in long-span double girder cranes. Anti-sway devices or load stabilizers are attachments that reduce load movement during travel.

Benefits:

-

Enhances operational safety by preventing swinging loads.

-

Increases lifting precision, especially for delicate or tall items.

-

Reduces the risk of load damage and accidents in confined spaces.

These systems can be mechanical, electronic, or hydraulic, depending on the complexity and precision required.

7. Limit Switches and Safety Interlocks

Limit switches are essential safety accessories that prevent the crane from exceeding its designated movement range. Similarly, safety interlocks ensure that certain operations cannot occur unless predefined conditions are met.

Benefits:

-

Prevents collisions and over-travel, protecting both the crane and surrounding infrastructure.

-

Enhances operator safety and reduces downtime due to accidents.

-

Supports compliance with international crane safety standards.

Limit switches can be customized for hook height, trolley position, and bridge travel, providing comprehensive protection.

8. Remote Monitoring and Automation Systems

Modern EOT cranes can be upgraded with remote monitoring and automation accessories. These systems allow operators and managers to monitor crane operation in real time, analyze performance metrics, and even automate repetitive lifting cycles.

Benefits:

-

Enables predictive maintenance by monitoring motor, brake, and hoist conditions.

-

Increases operational efficiency through automation of repetitive tasks.

-

Reduces human error, enhancing safety and productivity.

Integration with Industry 4.0 solutions allows for complete data tracking, remote diagnostics, and operational optimization.

9. Special Hooks and Load Adaptors

Depending on the load type, custom hooks, spreader beams, and lifting adaptors may be necessary. These attachments allow cranes to handle unique shapes or multiple loads simultaneously.

Benefits:

-

Expands the crane’s capability to lift specialized or oversized loads.

-

Ensures safe distribution of load weight to prevent structural damage.

-

Reduces manual rigging efforts, saving time and labor.

Custom lifting solutions can be designed to match specific industrial requirements, from cylindrical rolls to heavy machinery components.

10. Environmental and Protective Accessories

For cranes operating in harsh environments such as coastal areas, chemical plants, or outdoor industrial yards, protective accessories are crucial. These include weather covers, corrosion-resistant coatings, and dust-proof enclosures for electrical components.

Benefits:

-

Prolongs the life of the crane by protecting it from environmental damage.

-

Reduces maintenance frequency and associated costs.

-

Ensures safe operation under adverse weather conditions.

Optional heaters and air conditioners for operator cabins can also enhance operator comfort and safety in extreme climates.

Conclusion

EOT cranes are highly versatile, but their functionality and efficiency can be significantly enhanced through carefully selected attachments and accessories. From improving operational safety with anti-sway devices and limit switches, to handling specialized loads with magnets, grabs, or vacuum systems, these add-ons enable cranes to adapt to a wide range of industrial needs.

Moreover, modern accessories such as remote monitoring systems and automation tools are reshaping crane operations, allowing industries to increase efficiency, ensure safety, and achieve precise load handling.

Ultimately, the selection of optional EOT crane attachments should be guided by operational requirements, load characteristics, and environmental conditions. Investing in these accessories not only improves functionality but also enhances the return on investment by optimizing crane performance, reducing downtime, and increasing workplace safety.

For industrial operators, staying informed about the latest crane accessories and integrating them into operations can transform a standard EOT crane into a highly adaptable and efficient lifting solution, ready to meet the demands of modern industrial environments.