It probably goes without mentioning that millions of intelligent people look at huge piles of recyclables and think about making money by turning free stuff into something of value. It just so happens that that’s not an impossible dream, and researchers have discovered ways to utilize a waste plastic pyrolysis machine. It’s even possible to do in your own backyard, but quite a bit more difficult. Getting consultation from manufacturer of rubber pyrolysis machine for sale is also a good idea.

Plastic Waste Degrades Very Slowly

One of the great selling points of many plastics are the incredibly long times that it takes to degrade. You don’t need to worry that your Pepsi or gallon of milk is going to leak all over the fridge, in fact the bottle could outlive you and your kids long after you’ve thrown it away. You can find more information about Beston Pyrolysis here www.Bestonmachinery.com.

This presents a serious problem throughout the world, where plastic is piling up in landfills, filling oceans, and clogging rivers. Some plastics may stay intact for up to one thousand years when buried underground. Sure, some plastics can be recycled, but each different kind of plastic needs a different process, and sorting them is hard to automate.

The typical way that plastics are sorted is by human workers reading the resin ID codes printed on the bottles. Of course, many of the soda bottles can be done easily, but the rest takes time. Other recycled items like metals are easy to sort by garbage sorting machine, and worth far more when melted down.

Most Plastics Are Not Recyclable At All

When you look at a plastic bottle you’ll notice it has stamp on it with a number, that number is the type of resin that is used to make it, and determines how it can be recycled. For the most part only PET #1 and HDPE #2 are readily recyclable, and they’re usually sent to China for that.

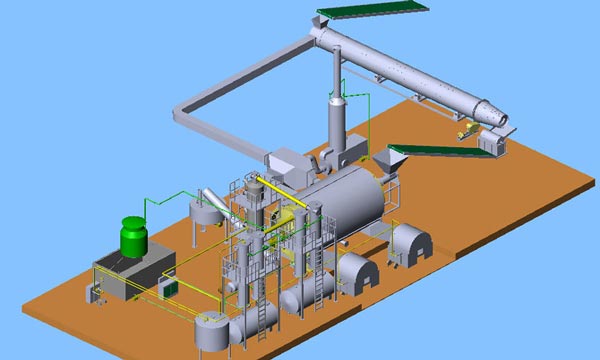

Most other plastics are either not worth the effort, or the plastic doesn’t lend itself to being melted down, it separates into other components and won’t reform into a usable plastic again. On the other hand, it’s possible to break down the plastic and gain oil in the waste plastic recycling equipment.

Breaking Down The Plastic Is Called Cracking Or Pyrolysis

Most plastics are made from long chains of atoms like carbon, oxygen, sulfur and nitrogen. When heated to a high temperature some of the individual chemicals will separate out into usable components. It’s estimated that about 86% of what’s left after heating is liquid oil that can be used as heating oil or burned to make electricity.

Turning waste plastics into a usable fuel oil is practically a dream come true, especially based on the millions of tons of waste plastics the world is dealing with. If the plastic to fuel process can be shown to be cost effective, produce no toxins, and save on landfill costs then it may be the solution that saves the earth from one of it’s more serious problems.